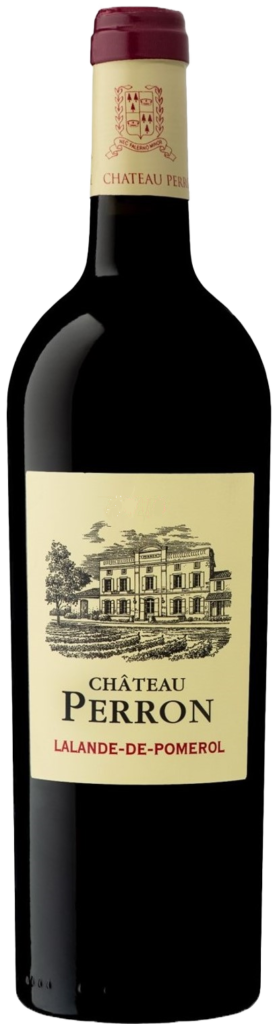

Grand Vin de Lalande-de-Pomerol. Propriété familiale depuis 1958, engagée dans l’agriculture biologique et le respect de son terroir.

Tradition / Convivialité / Buvabilité

Tradition Convivialité Buvabilité

Une expérience

Vin de partage et de convivialité, avec le Perron on ne se trompe pas, il correspondra à tout type d’occasion.

Une expérience

Vin de partage et de convivialité, avec le Perron on ne se trompe pas, il correspondra à tout type d’occasion.

La Propriété

Le Château PERRON s’étend sur 36 hectares de vignes en AOC Lalande-de-Pomerol.

Histoire

Le Château PERRON, datant de 1642 est l’une des propriétés les plus anciennes de la commune.

Nos Vins

Nous avons à cœur de restituer dans les vins du Château PERRON toute l’excellence de notre terroir.

Agriculture Biologique

Nous sommes depuis 2022 Certifié Agriculture Biologique. C’est avec fierté que nous portons ce label.

L’agriculture Biologique a pour volonté de réconcilier l’homme avec la Terre, sa terre, son sol, et le végétal qu’il y cultive.